Since I am bringing two small planes to the seminar I thought I might just make a bigger one for it as well. I'm dong this one a little differently.

Basically the bed angle is staying the same but the front angle will be 50 degrees and I'm going to put a radius on that angle as well. A few things that I have read say that it helps the shavings push through easier. Alot of people will use 60 degrees but I didn't like the way it was going to work on this plane.

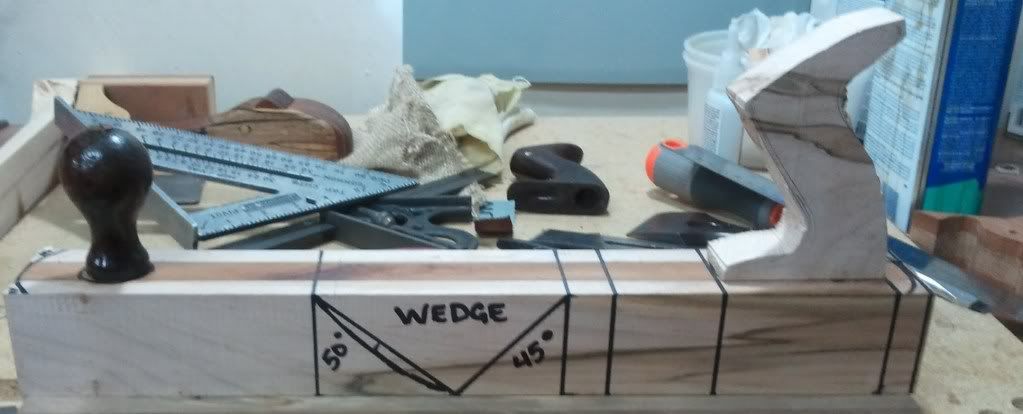

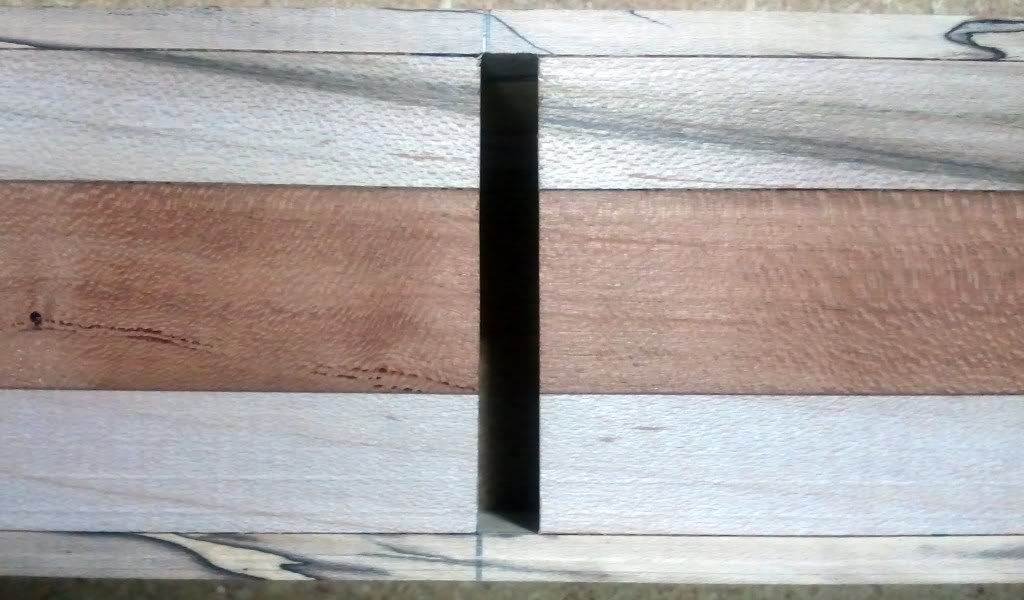

Here are a couple of shots of the layout of the plane.

This is the side you can see the general layout of the plane from here.

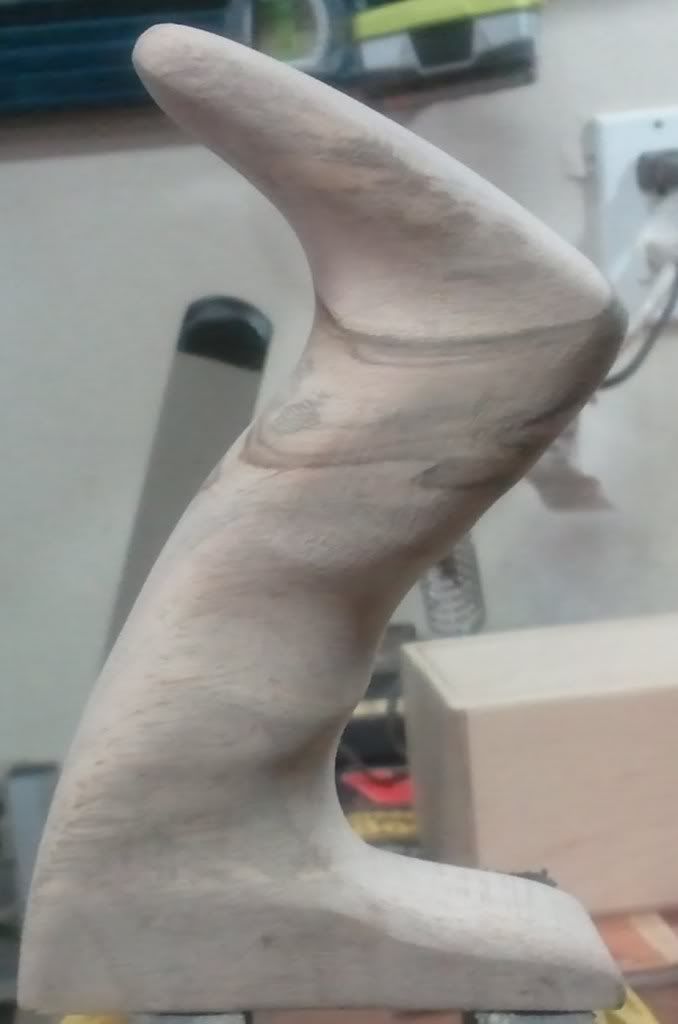

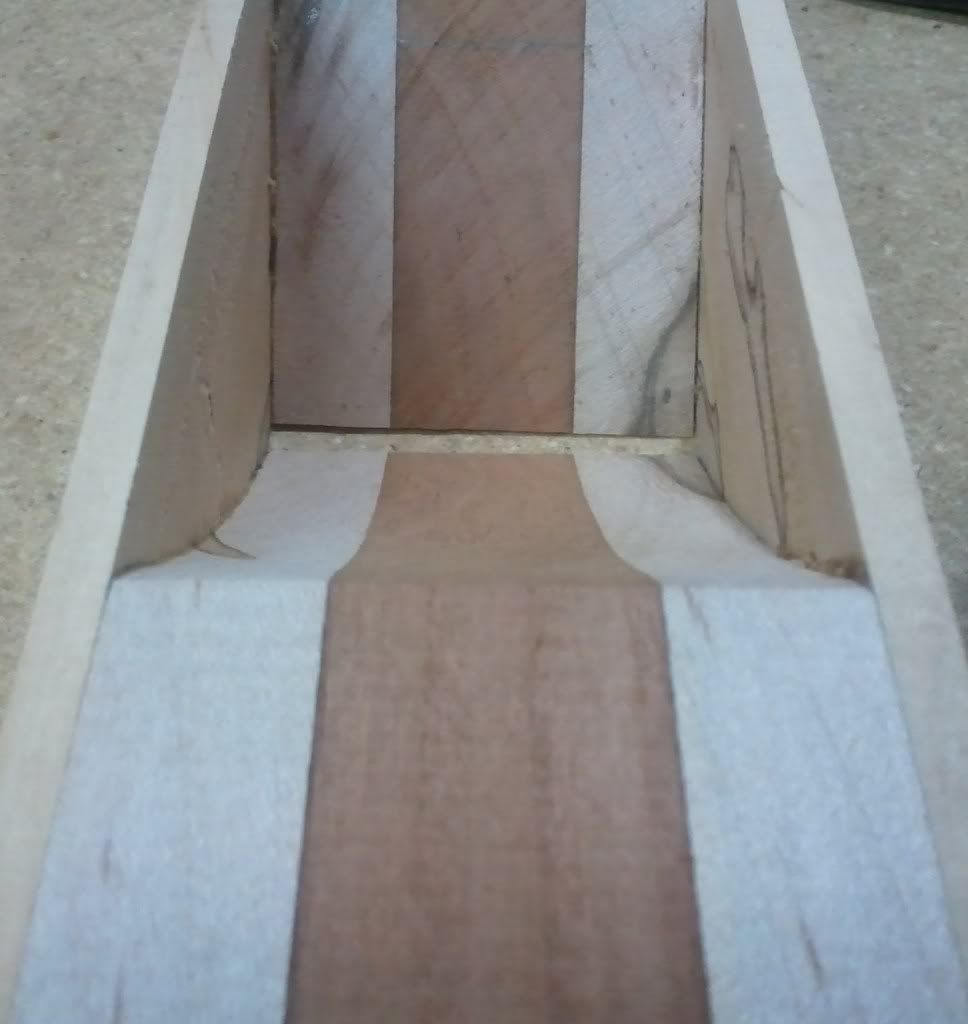

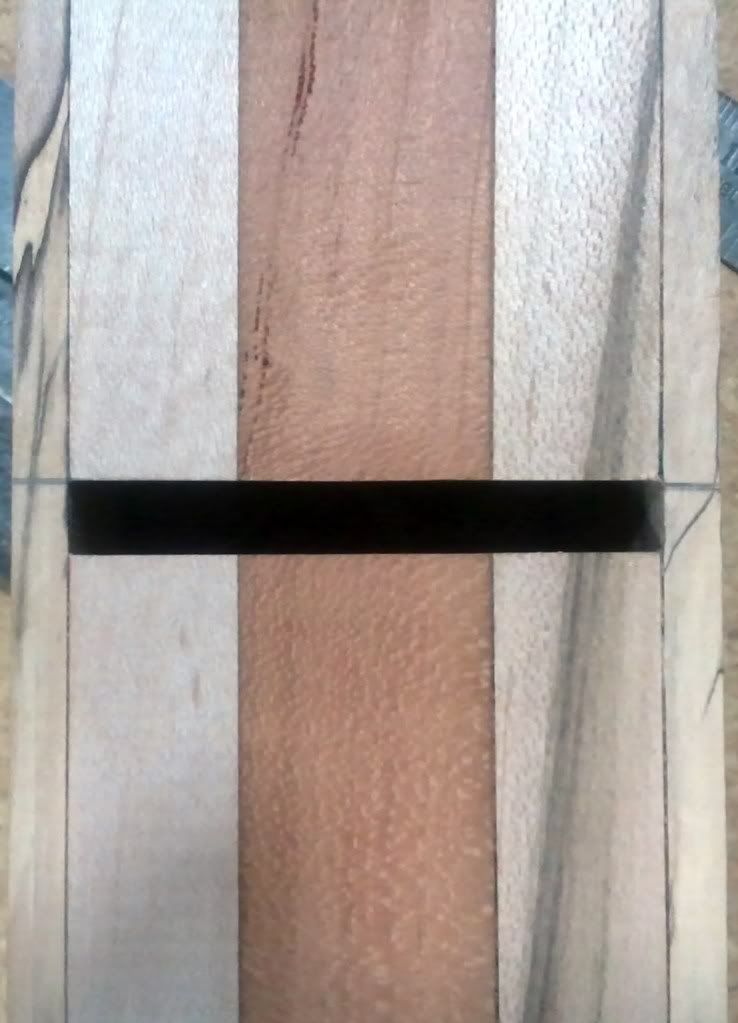

Here is a top view, I am thinking i am going to put a tote on this one and see how that works out, not 100% on that yet.

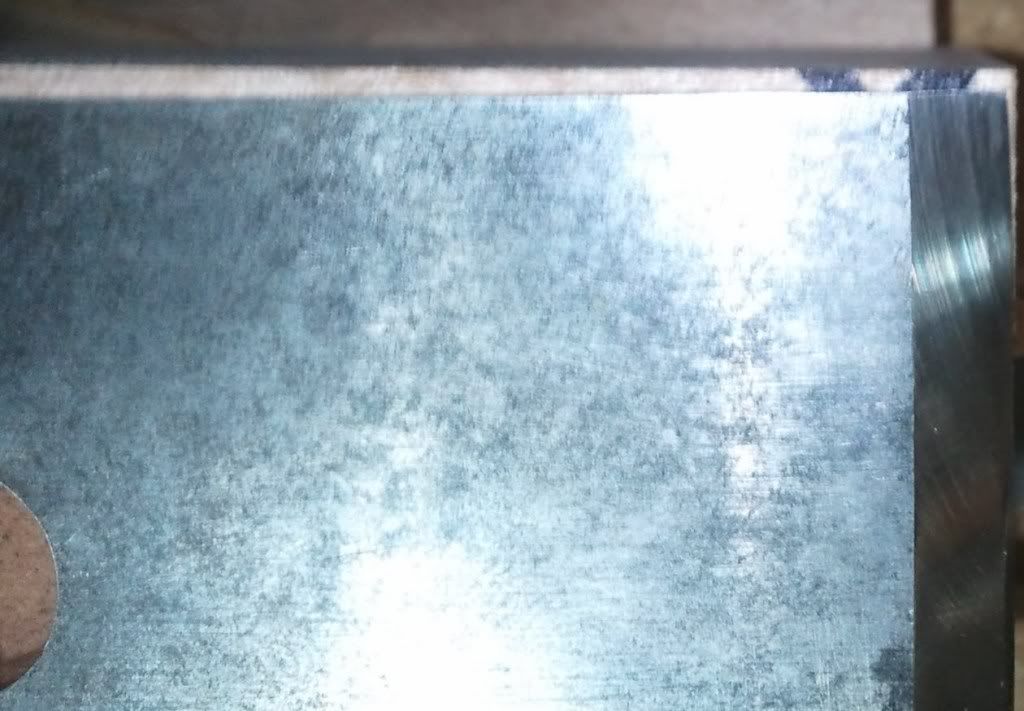

Mike Davis just so you know I'm building this around an old sargent iron and chip breaker that I got from a flea market. Mixing the two worlds.

Basically the bed angle is staying the same but the front angle will be 50 degrees and I'm going to put a radius on that angle as well. A few things that I have read say that it helps the shavings push through easier. Alot of people will use 60 degrees but I didn't like the way it was going to work on this plane.

Here are a couple of shots of the layout of the plane.

This is the side you can see the general layout of the plane from here.

Here is a top view, I am thinking i am going to put a tote on this one and see how that works out, not 100% on that yet.

Mike Davis just so you know I'm building this around an old sargent iron and chip breaker that I got from a flea market. Mixing the two worlds.