Hello all,

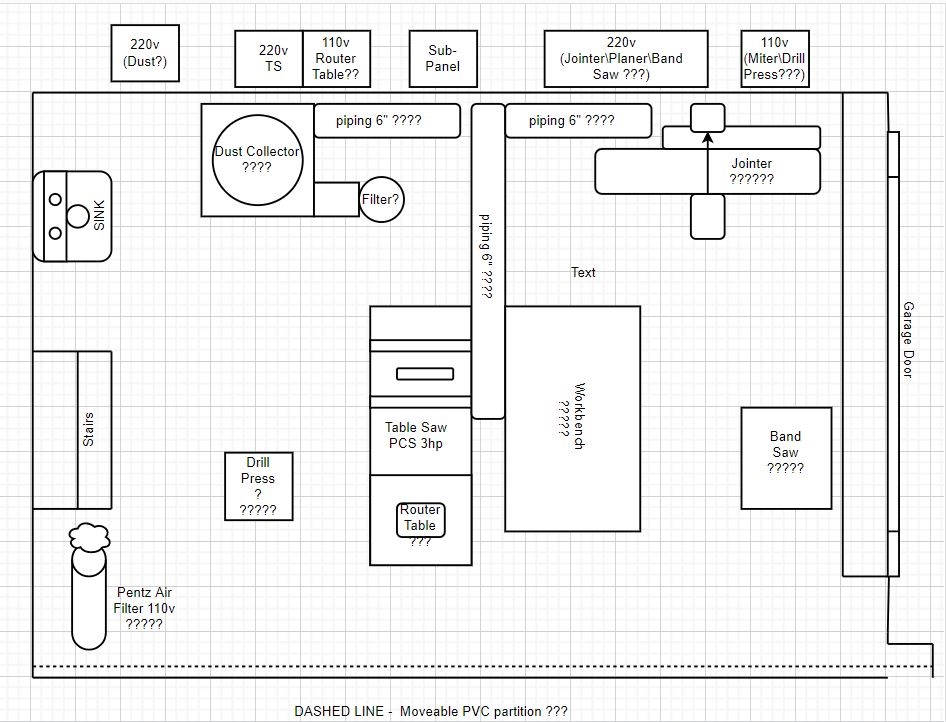

I have a house with an attached 3 car garage but, for now, I am limited to using only 1 of the spaces (other side has 2 vehicles). My shop is spaced at 13' wide x 19' long. In the attached picture, each large square is 1' and each smaller square is 3".

I have noted in the attached picture, as best as I can, what items are what (stairs\tools\electrical\etc.).

Currently, I own a 3hp table saw, some handheld routers, track saw with all variety of lengths (up to 108"?), benchtop planer, 12" miter saw, & the usual (small hand held tools).

Since the price of wood is more than the price of gold, I figured, why not just concentrate on shop design\layout\lights\partition install\DC install, before selling a kidney...?

Above is (obviously) a layout of my garage. The subpanel and 110\220 outlets are there but, everything "assigned" to the outlets (with a "?") are not hard set.

Also, all of the objects labeled with a "?" do not exist (yet?). If I were to have these tools, they would be on mobile bases, so I could "easily" move them around. Not sure I'd want to move a "large" jointer around, so if I were to get that (8" floor model), it would most likely stay wherever it finds a "proper" location.

I don't currently have a DC, just a HF motor with Rikon impeller installed (the DC motor has never been used). Last year I was thinking about using the HF motor with a cyclone, filter, etc.. but, after reading and reading some more, I am heavily rethinking that idea. I know it is "spendy" and will take up premium space in my garage but, what do you think about a dedicated (wall/stand - if I go this route, it'll most likely be the stand) 3HP+ DC? From what I can tell, the "2" DC choices, unless anyone else knows of a "better" option, are V-3000 & CV1800 (5HP?? Extreme overkill!? NOT leaning this way).

Forgot to mention... I am not sure what to do with my 12" DeWalt miter saw (DWS779 - I think is the model). I don't think a dedicated spot would be best but, what do you think?

What are your thoughts on my garage layout? Suggestions, recommendations, constructive "criticism" is welcomed, questions, etc.

Thanks! Rory

I have a house with an attached 3 car garage but, for now, I am limited to using only 1 of the spaces (other side has 2 vehicles). My shop is spaced at 13' wide x 19' long. In the attached picture, each large square is 1' and each smaller square is 3".

I have noted in the attached picture, as best as I can, what items are what (stairs\tools\electrical\etc.).

Currently, I own a 3hp table saw, some handheld routers, track saw with all variety of lengths (up to 108"?), benchtop planer, 12" miter saw, & the usual (small hand held tools).

Since the price of wood is more than the price of gold, I figured, why not just concentrate on shop design\layout\lights\partition install\DC install, before selling a kidney...?

Above is (obviously) a layout of my garage. The subpanel and 110\220 outlets are there but, everything "assigned" to the outlets (with a "?") are not hard set.

Also, all of the objects labeled with a "?" do not exist (yet?). If I were to have these tools, they would be on mobile bases, so I could "easily" move them around. Not sure I'd want to move a "large" jointer around, so if I were to get that (8" floor model), it would most likely stay wherever it finds a "proper" location.

I don't currently have a DC, just a HF motor with Rikon impeller installed (the DC motor has never been used). Last year I was thinking about using the HF motor with a cyclone, filter, etc.. but, after reading and reading some more, I am heavily rethinking that idea. I know it is "spendy" and will take up premium space in my garage but, what do you think about a dedicated (wall/stand - if I go this route, it'll most likely be the stand) 3HP+ DC? From what I can tell, the "2" DC choices, unless anyone else knows of a "better" option, are V-3000 & CV1800 (5HP?? Extreme overkill!? NOT leaning this way).

Forgot to mention... I am not sure what to do with my 12" DeWalt miter saw (DWS779 - I think is the model). I don't think a dedicated spot would be best but, what do you think?

What are your thoughts on my garage layout? Suggestions, recommendations, constructive "criticism" is welcomed, questions, etc.

Thanks! Rory