In September I wrote an article on making sand-shaded fan inlays that I planned to use in a Federal-style card table (Post | NCWoodworker.com). Over the holidays I've made a lot of progress, including finally getting the inlayed into the table legs. Here's a few pictures of how it's coming together as I dry-fit all the pieces. My current step is making the drawer.

This image shows how the table will look with the drawer closed. At this stage I've oiled and filled the walnut apron pieces. There is a cock beading yet to be attached to the bottom of the apron, but otherwise the detail is complete.

One of the back legs is hinged and will swing outwards to support the top when unfolded.

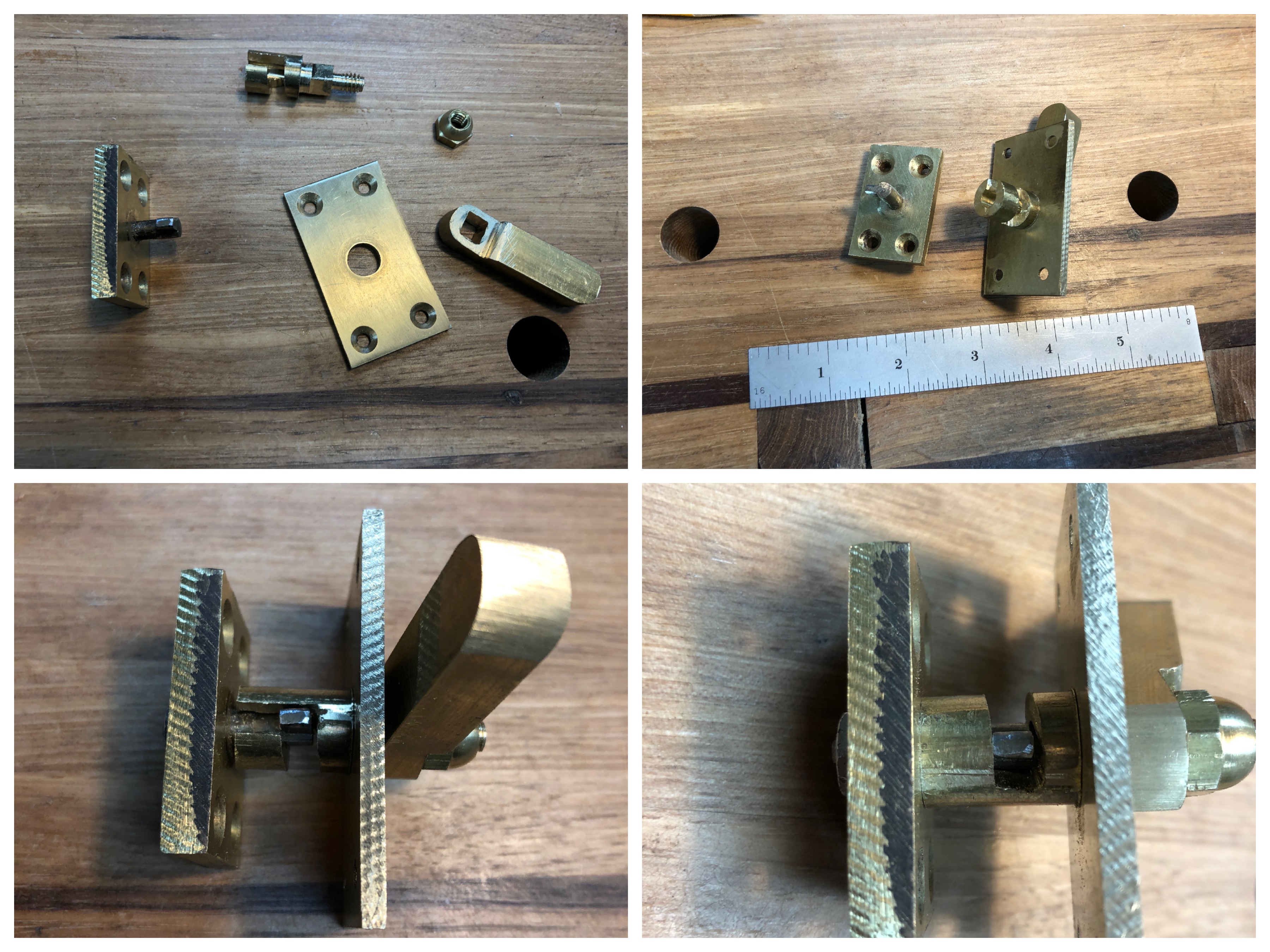

After looking at some examples in the MESDA collection I noticed that the swinging leg was often slightly open on these tables. After 200+ years of use I can easily see the wooden hinge loosening up a bit. To prevent this happening I came up with a simple locking mechanism that mounts on the inside of the back fixed apron with a "key" attached to the swinging apron. With a quarter-turn the leg is securely locked in place.

The handle turns a brass cylinder that acts as a cam. When turned to the open position it allows the key to be inserted. As the cylinder is rotated the cam pulls the plate with the key tighter. The next couple of pictures show it installed.

Closed.

Open.

Once I complete the drawer I'll disassemble everything and begin applying the shellac and making the top. Stay tuned for more pictures when it's done.

This image shows how the table will look with the drawer closed. At this stage I've oiled and filled the walnut apron pieces. There is a cock beading yet to be attached to the bottom of the apron, but otherwise the detail is complete.

One of the back legs is hinged and will swing outwards to support the top when unfolded.

After looking at some examples in the MESDA collection I noticed that the swinging leg was often slightly open on these tables. After 200+ years of use I can easily see the wooden hinge loosening up a bit. To prevent this happening I came up with a simple locking mechanism that mounts on the inside of the back fixed apron with a "key" attached to the swinging apron. With a quarter-turn the leg is securely locked in place.

The handle turns a brass cylinder that acts as a cam. When turned to the open position it allows the key to be inserted. As the cylinder is rotated the cam pulls the plate with the key tighter. The next couple of pictures show it installed.

Closed.

Open.

Once I complete the drawer I'll disassemble everything and begin applying the shellac and making the top. Stay tuned for more pictures when it's done.