Whoa, cowboys- I hate to say this but there is a lot of bad or misleading info in this thread, e.g.

The K factor in 2-45s is not enough to worry about. Bend in pipe friction with dust will be small even with chips.

All sources of static pressure are important because they are cumulative. A single, long sweep bend is always better (generates less static pressure) than two 45's, for two reasons- the radius of two 45's (of PVC in sizes commonly available) is less than most long sweep bends and the extra joint where the two 45's meet generates turbulence and even more static pressure (resistance to flow).

What is more essential is how many inches of water does it draw. That is the true measure of how well most of these systems will perform.

No, no, no- what do you mean by "these systems"?

Dust collection systems are designed to capture large volumes of dust laden air at the source- that requires high CFM. Obviously static pressure is also required to overcome resistance in the ducting, but not at the expense of CFM. Look at the point on the fan curve where any decent DC operates best- it isn't where the static pressure is highest! It falls somewhere in the middle section. Don't confuse a dust collector with a vacuum!!! They are very different animals with different physics and engineering.

No will disagree on this - CFM is one measure but if the draw is not strong (inches) then cfm will not be as effective, there are other factors but for most here their dust systems are simplistic.

Without getting wonky Brunelli principle shows why.

Since, in the case of dust collection, air behaves like an incompressible gas,

Bernoulli's equation is valid, but not the way you are implying. You might want to re-read your fluid dynamics text. Dust collectors don't need high SP because the dust and chips are typically light and the CFM is high (volume & velocity are high). Shopvacs need high SP (draw?) (typically > 5 to 10 times what a DC generates) because they must draw through small diameter hoses and wands (typically less than 2-1/4" in diam.) so must overcome very high resistance and because they are only designed to pick up stationary dust from a very small surface area. Try it yourself- move a shopvac nozzle 2" or so away from a pile of dust and see what happens- nothing is picked up. Then thow the dust in the air and see how much of it you can get with a shopvac hose- not much and almost nil compared to what a DC with 6" hose will get!!!!

Shop vacs tend to have higher air flow than DC systems. That's the design of a shop vac.

No, no, no- you are confusing air flow with static pressure (or suction if you want to use a lay term). A typical shopvac operates at

45-60 in. of water static pressure and

115-130 CFM. Good if you want to pick up a bowling ball but really terrible if you need to capture airborne dust!!! A typical dust collector operates at

7 - 10 in. of water static pressure, however, depending on the model and duct system, will move anywhere from

800 - 1500 CFM. A DC has much higher

air flow which what is needed to capture dust!

Sorry, guys, you might want to listen to Rush!

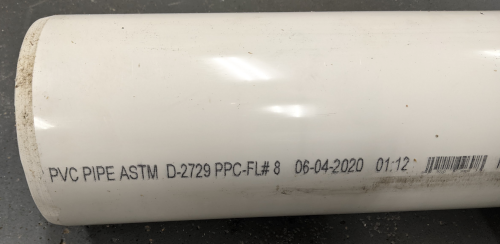

Rush, nice idea for long sweep elbows. I suspect you can use your technique for any amount of bend, too.