I took a chance on this very used 30+ year-old Shopsmith 12” planer and found it very interesting. I thought I’d share what I found in case others ran across one for sale.

First, its relatively light weight with the castings being aluminum. On my specimen, the 28” long bed is aluminum with a polished steel overlay. There was some bed slop so I got a slight snipe about 1-3/4” from the end.

The motor is a standard NEMA capacitor start 1-1/2 HP that’s run on 120 volts. There is a separate DC feed motor with its own speed control. There may be a way to re-wire things for 240 volt, but I didn’t explore that.

The stand has sheet metal legs and foot-adjustable casters. An optional dust hood was included but I didn’t try it. I did all of my testing without the covers and I didn’t think it made all that big of a mess.

Once I got the aluminum pulleys straightened out, it ran very quietly. At idle, I would compare the noise to about the same as a good quality step pulley drill press running at medium speed. This is a big asset to a home hobby shop. No worries about a nearby airport calling and complaining about the noise.

As with any used planer for sale, the knives were trashed, but included were two sets of dull knives. I sent off a couple of sets to have sharpened at $30.00 per set. A new set is over a C-note from Shopsmith and likely not as sharp.

When I picked up the knives from the sharpening shop they told me that they’d never seen any knives like this. The knives were tapered from back to front, and not an even 1/8” like I’d assumed. There was even a bevel on the back edge for some reason. The knives are held in by down pressure from the locking bars so a tapered knife body makes the knives particularly secure. The knives stick out from the 2” diameter cutterhead a little over 1/8”, so that’s a lot of knife exposed and thus the extra safety measure.

The knife installation took about 45 minutes once I’d figured out what I’d need and found a dial indicator base that would work. Shopsmith has a good video on setting the knives with a dial indicator, but that method looked a little awkward to me since I had an indicator base that would work off the cutterhead.

The serrated infeed roller and the rubber coated outfeed roller are about 5-1/2” apart. For short stock, this is great. I dressed a scrap of rough oak that was 8” long with no problem. These rollers can’t be adjusted up or down so the knife extension from the cutterhead is somewhat critical. There’s also a bar with anti-kickback pawls.

The raise/lower crank is 1/16” of movement per turn. That makes for easily calculated adjustments.

It appears that Shopsmith still supports this machine. That’s comforting to know. I emailed the tech support people with a question They got back to me within 48 hours with a cogent reply. I think I could have called and gotten a quick answer, but the question wasn’t all that important.

Clearly, this planer is no Powermatic 100, but I don’t think it was meant to be. In my opinion, it’s a good lightweight planer for hobby woodworking use and at least as good as the suitcase screamers that were made somewhere other than Ohio.

Planer in the seller's shop.

Label on my planer

Covers removed and knives removed

Drive motor side

pulley side. Cast iron pulleys would be better.

Putting the knife gauge on the cutterhead

Checking the knife for zero

Knives set with the screw-in bars.

Side view, covers installed

Shown beside my 18" daily driver planer just for scale.

Side view, covers removed

Front view, covers removed

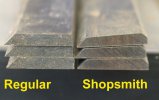

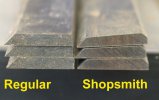

End view of the shopsmith knives compared to a regular (1/8" thick) set of knives

First, its relatively light weight with the castings being aluminum. On my specimen, the 28” long bed is aluminum with a polished steel overlay. There was some bed slop so I got a slight snipe about 1-3/4” from the end.

The motor is a standard NEMA capacitor start 1-1/2 HP that’s run on 120 volts. There is a separate DC feed motor with its own speed control. There may be a way to re-wire things for 240 volt, but I didn’t explore that.

The stand has sheet metal legs and foot-adjustable casters. An optional dust hood was included but I didn’t try it. I did all of my testing without the covers and I didn’t think it made all that big of a mess.

Once I got the aluminum pulleys straightened out, it ran very quietly. At idle, I would compare the noise to about the same as a good quality step pulley drill press running at medium speed. This is a big asset to a home hobby shop. No worries about a nearby airport calling and complaining about the noise.

As with any used planer for sale, the knives were trashed, but included were two sets of dull knives. I sent off a couple of sets to have sharpened at $30.00 per set. A new set is over a C-note from Shopsmith and likely not as sharp.

When I picked up the knives from the sharpening shop they told me that they’d never seen any knives like this. The knives were tapered from back to front, and not an even 1/8” like I’d assumed. There was even a bevel on the back edge for some reason. The knives are held in by down pressure from the locking bars so a tapered knife body makes the knives particularly secure. The knives stick out from the 2” diameter cutterhead a little over 1/8”, so that’s a lot of knife exposed and thus the extra safety measure.

The knife installation took about 45 minutes once I’d figured out what I’d need and found a dial indicator base that would work. Shopsmith has a good video on setting the knives with a dial indicator, but that method looked a little awkward to me since I had an indicator base that would work off the cutterhead.

The serrated infeed roller and the rubber coated outfeed roller are about 5-1/2” apart. For short stock, this is great. I dressed a scrap of rough oak that was 8” long with no problem. These rollers can’t be adjusted up or down so the knife extension from the cutterhead is somewhat critical. There’s also a bar with anti-kickback pawls.

The raise/lower crank is 1/16” of movement per turn. That makes for easily calculated adjustments.

It appears that Shopsmith still supports this machine. That’s comforting to know. I emailed the tech support people with a question They got back to me within 48 hours with a cogent reply. I think I could have called and gotten a quick answer, but the question wasn’t all that important.

Clearly, this planer is no Powermatic 100, but I don’t think it was meant to be. In my opinion, it’s a good lightweight planer for hobby woodworking use and at least as good as the suitcase screamers that were made somewhere other than Ohio.

Planer in the seller's shop.

Label on my planer

Covers removed and knives removed

Drive motor side

pulley side. Cast iron pulleys would be better.

Putting the knife gauge on the cutterhead

Checking the knife for zero

Knives set with the screw-in bars.

Side view, covers installed

Shown beside my 18" daily driver planer just for scale.

Side view, covers removed

Front view, covers removed

End view of the shopsmith knives compared to a regular (1/8" thick) set of knives