Hello...

I recently purchased a lot of rough sawn boards (6" - 13" wide) and am "close" to directing my funds towards a new jointer.

I'm nothing more than a garage hobbyist, but would be open to doing some casual commission pieces down the road, so I am 99.99% set on an 8" jointer. The reason I say an 8" is... 12" is insanely pricey and I'm thinking an 8" would be ideal and then use the rest of the funds towards a "proper" planer (15"). I'd like a 12" jointer, but most are usually 5hp and require a 30A circuit (all of mine are 20A and upgrading 1 to a 30A would require electrical skills that I do not have), also weigh a lot (850++ lbs). 12" are usually $5,500+, too.

Thought about a 12" J/P, but those have really short beds (about 55"?) and the planer is only 12". Looked at a Hammer A3-31 and Minimax FS30X, but those are 4.x HP and (I believe) require a 25A/30A circuit. Also, I am not sure of their prices, since I can't seem to find it listed anywhere (have to call/email for quote). This route would give me a 12" jointer, but how much would I be sacrificing (besides the obvious 3" of planing ability) with regards to a larger planing surface?

My woodworking side of the garage is 13' x 20'. I have a 60 amp sub-panel with several dedicated circuits.

Some 110 and some 220... all 20A. I'd throw most/all of my bigger tools on mobile bases, too, so I could do 2 machines vs the 1 J/P combo.

I have a 3hp SawStop PCS, track saw, Dewalt 734 planer (plan on selling it down the road), Miter saw, and some other misc. tools.

Sure, some/all of the above mentioned tools could straighten & "flatten" a board, but most likely would need a jig of sorts, so I can run it through the planer. To me, a bunch of time wasted & "unnecessary" steps to get subpar results, maybe slightly better than sub-par.

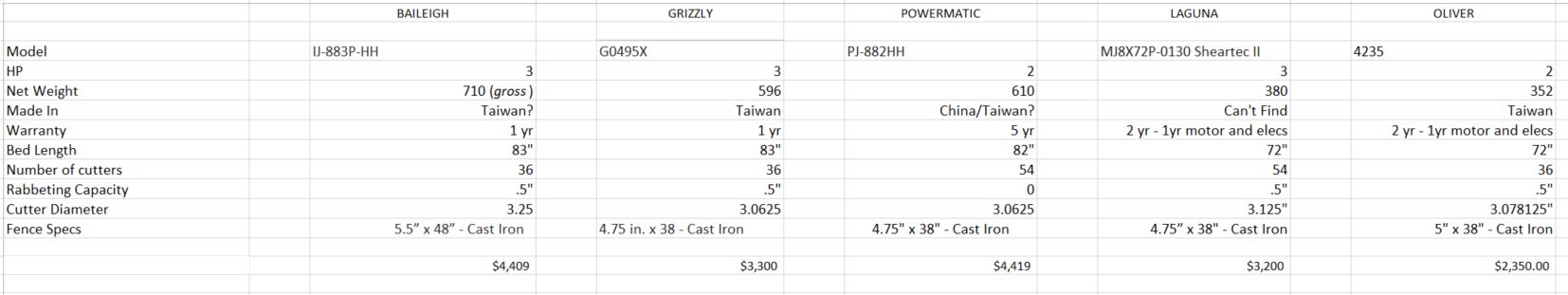

Regardless... yesterday I put together a spreadsheet comparing (5) 8" jointers. Overall, the Grizzly looks like a winner, but maybe another set of eyes can chime in?

ALL jointers I am looking at are new, with a parallelogram table, and a spiral/helical head.

I know Grizzly has a "Spring/Summer" sales event.. and code: APRIL10 (Wilkerson?) might work during their sales time? If not, the APRIL10 still knocks a few hundred off of their products during the rest of the year. Also, I've done a decent amount of research on this Grizzly, but other input would be appreciated, especially with comparison to other 8" jointers and jointers I might be missing. Is the Grizzly G0495x the "best/better" choice?

Regardless of what is mentioned above, with regards to an 8" jointer, I'd be open to the idea of a J/P combo...but not sure it would be worth it. Also, would the back and forth mess with the accuracy?

The following companies make J/P combos:

Baileigh

Hammer

Minimax

Jet

Rikon

Overall, I want "superior" build quality, accuracy, cost effective but don't want to sacrifice the other items (build quality/ accuracy/ etc.), helical/spiral, parallelogram, new. Basically, the "best" overall for the price.

Opinions, ideas, suggestions, comments...etc.

Thanks and looking forward to hearing from you.

Rory

I recently purchased a lot of rough sawn boards (6" - 13" wide) and am "close" to directing my funds towards a new jointer.

I'm nothing more than a garage hobbyist, but would be open to doing some casual commission pieces down the road, so I am 99.99% set on an 8" jointer. The reason I say an 8" is... 12" is insanely pricey and I'm thinking an 8" would be ideal and then use the rest of the funds towards a "proper" planer (15"). I'd like a 12" jointer, but most are usually 5hp and require a 30A circuit (all of mine are 20A and upgrading 1 to a 30A would require electrical skills that I do not have), also weigh a lot (850++ lbs). 12" are usually $5,500+, too.

Thought about a 12" J/P, but those have really short beds (about 55"?) and the planer is only 12". Looked at a Hammer A3-31 and Minimax FS30X, but those are 4.x HP and (I believe) require a 25A/30A circuit. Also, I am not sure of their prices, since I can't seem to find it listed anywhere (have to call/email for quote). This route would give me a 12" jointer, but how much would I be sacrificing (besides the obvious 3" of planing ability) with regards to a larger planing surface?

My woodworking side of the garage is 13' x 20'. I have a 60 amp sub-panel with several dedicated circuits.

Some 110 and some 220... all 20A. I'd throw most/all of my bigger tools on mobile bases, too, so I could do 2 machines vs the 1 J/P combo.

I have a 3hp SawStop PCS, track saw, Dewalt 734 planer (plan on selling it down the road), Miter saw, and some other misc. tools.

Sure, some/all of the above mentioned tools could straighten & "flatten" a board, but most likely would need a jig of sorts, so I can run it through the planer. To me, a bunch of time wasted & "unnecessary" steps to get subpar results, maybe slightly better than sub-par.

Regardless... yesterday I put together a spreadsheet comparing (5) 8" jointers. Overall, the Grizzly looks like a winner, but maybe another set of eyes can chime in?

ALL jointers I am looking at are new, with a parallelogram table, and a spiral/helical head.

I know Grizzly has a "Spring/Summer" sales event.. and code: APRIL10 (Wilkerson?) might work during their sales time? If not, the APRIL10 still knocks a few hundred off of their products during the rest of the year. Also, I've done a decent amount of research on this Grizzly, but other input would be appreciated, especially with comparison to other 8" jointers and jointers I might be missing. Is the Grizzly G0495x the "best/better" choice?

Regardless of what is mentioned above, with regards to an 8" jointer, I'd be open to the idea of a J/P combo...but not sure it would be worth it. Also, would the back and forth mess with the accuracy?

The following companies make J/P combos:

Baileigh

Hammer

Minimax

Jet

Rikon

Overall, I want "superior" build quality, accuracy, cost effective but don't want to sacrifice the other items (build quality/ accuracy/ etc.), helical/spiral, parallelogram, new. Basically, the "best" overall for the price.

Opinions, ideas, suggestions, comments...etc.

Thanks and looking forward to hearing from you.

Rory