A new vise that I am assembling had too much toe-out. This can happen when little errors accumulate in the wrong direction.

The first step is to check that the screw is perpendicular to the leg. Note that the blade of the square is against the leg and the thicker square handle is against the round screw.

In this case, the bearing plate needs to be recessed a bit more. Remove the cross pivot pin from the leg and then remove the chop and screw assembly. I used a router plane to remove 2-3/64” from the bottom of the groove (it doesn’t take much).

Reassemble the vise and check again.

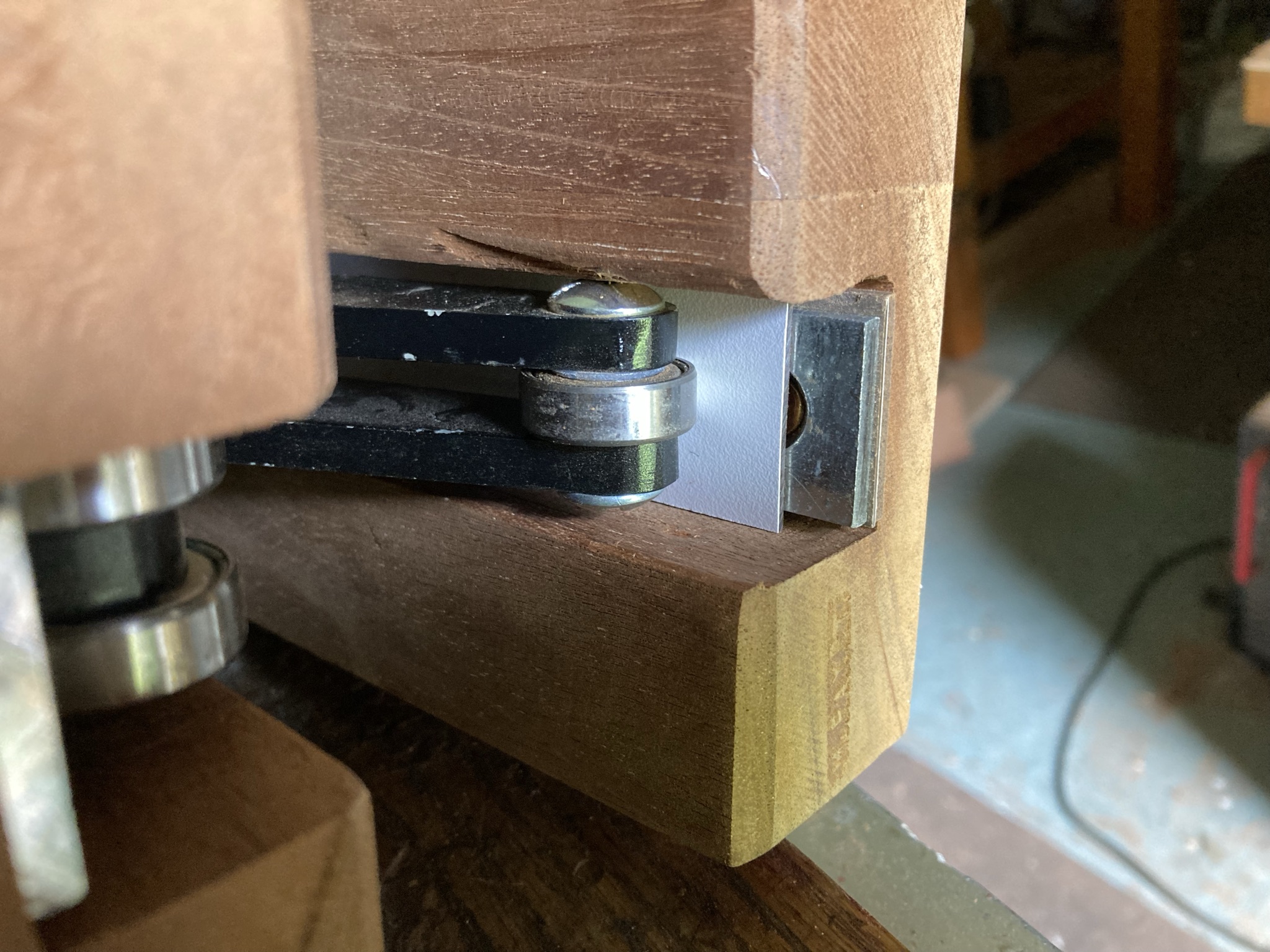

After getting the screw squared up, there was still some toe-out. To fix this, one needs to shim under the bearing plate in the chop. The bottom of the groove is open (on purpose) and you can just insert shim material (white laminate in this case) for testing on the surface of the chop bearing plate.

When you decide on the amount of shim needed, secure the shim material under the bearing plate. For this vise I used a strip of 1/8” tile board plus a strip of laminate. This X-cross vise mechanism is fairly stiff so 1/16” or so of toe-in is usually enough.

The first step is to check that the screw is perpendicular to the leg. Note that the blade of the square is against the leg and the thicker square handle is against the round screw.

In this case, the bearing plate needs to be recessed a bit more. Remove the cross pivot pin from the leg and then remove the chop and screw assembly. I used a router plane to remove 2-3/64” from the bottom of the groove (it doesn’t take much).

Reassemble the vise and check again.

After getting the screw squared up, there was still some toe-out. To fix this, one needs to shim under the bearing plate in the chop. The bottom of the groove is open (on purpose) and you can just insert shim material (white laminate in this case) for testing on the surface of the chop bearing plate.

When you decide on the amount of shim needed, secure the shim material under the bearing plate. For this vise I used a strip of 1/8” tile board plus a strip of laminate. This X-cross vise mechanism is fairly stiff so 1/16” or so of toe-in is usually enough.

Attachments

-

B98B6834-166C-4E2C-A409-B9B95BA9A089.jpeg534.8 KB · Views: 85

B98B6834-166C-4E2C-A409-B9B95BA9A089.jpeg534.8 KB · Views: 85 -

E6039677-C553-4373-A082-5CD2E9614297.jpeg909.3 KB · Views: 96

E6039677-C553-4373-A082-5CD2E9614297.jpeg909.3 KB · Views: 96 -

0834941B-E58E-4120-9A8C-905201CE4D7B.jpeg917.1 KB · Views: 84

0834941B-E58E-4120-9A8C-905201CE4D7B.jpeg917.1 KB · Views: 84 -

750825BC-5582-4BC6-A9A3-66D59883B404.jpeg909.3 KB · Views: 84

750825BC-5582-4BC6-A9A3-66D59883B404.jpeg909.3 KB · Views: 84 -

96E060CB-732A-48B4-8790-B048167A9C3C.jpeg658.2 KB · Views: 81

96E060CB-732A-48B4-8790-B048167A9C3C.jpeg658.2 KB · Views: 81

Last edited: