In case you’re wondering what Scott and I are talking about. There was a post that questioned the need for alignment of the jig. Someone thought I wasted a lot of time getting it set precisely. Then deleted the post after my answer. They also made mention of the rip fence comparing it to the motion of the tenon jig.

I didn’t just randomly decide to be anal about the adjustment. It needed to be correct for the tenons to be straight otherwise the joints would be crooked and the frames would not lie flat. The problem was there and I was trying to solve that problem.

Also, I don’t type all this because I love to type or see my thoughts in print. It is painful and time consuming. I try to document these moments in case someone else has the same experience and it may help them.

So, if your blade is not aligned to the crosscut guide slots in your table saw it will still cut straight, but the kerf will be wider than the blade. Because the front edge of the blade is cutting one side of the kerf and the back of the blade is cutting the other side of the kerf.

And if your blade is aligned but the fence is not. The fence will pinch the board if the rear of the fence is closer to the blade. If the fence is further away from the blade the board may do one or more of several odd cuts or dangerous things like kicking back.

So, ideally you should have the rip fence nearly parallel with the crosscut guide slots and away from the back of the blade no more that a few thousandths. Never closer at the rear.

In other words the board should be very slightly looser fit between the blade and the fence as it travels through.

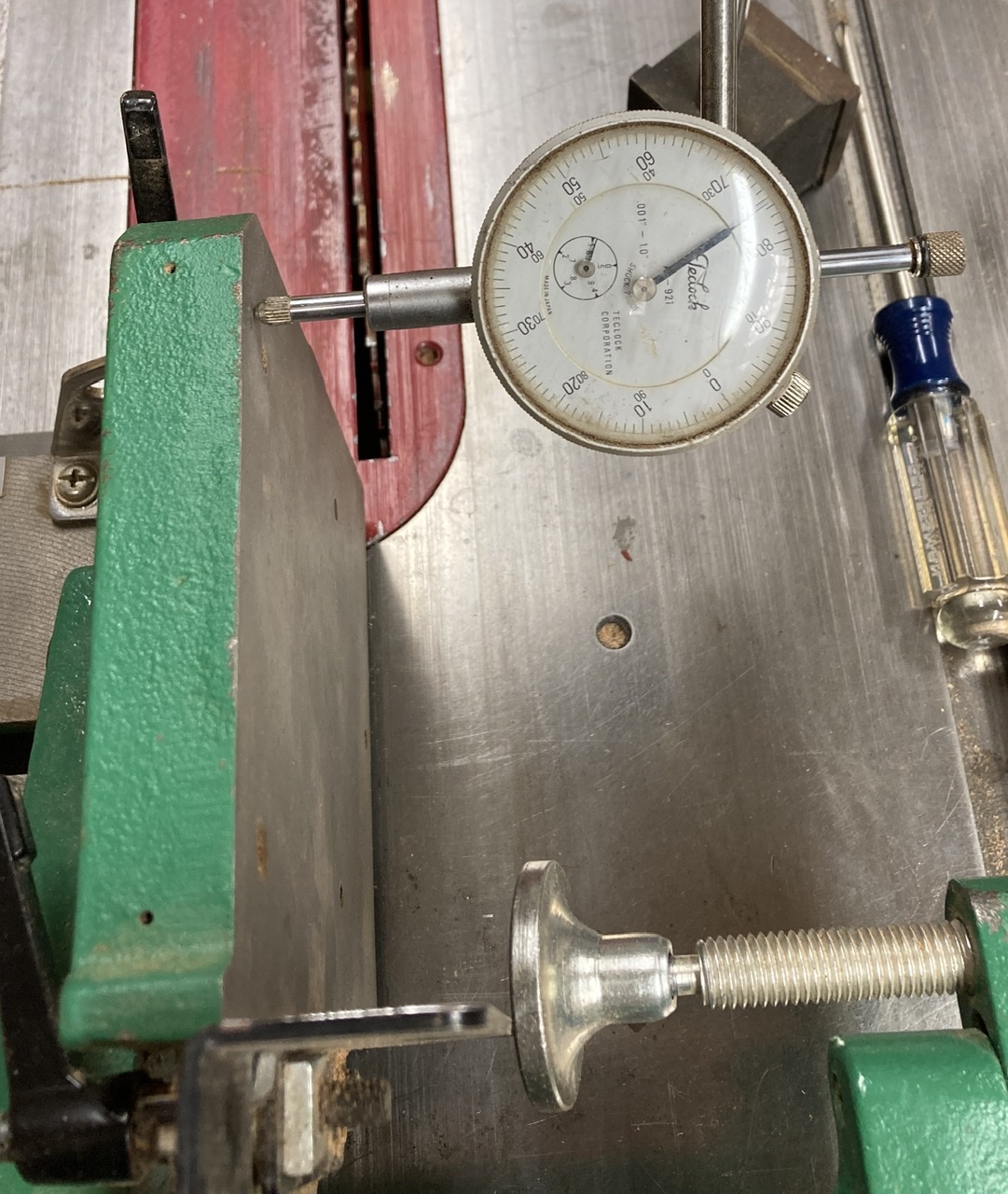

Now the third part of the equation is the crosscut guide. If the crosscut guide is not square to the crosscut guide slots the cut will be at an angle. Notice that I did not say square to the blade. We already established that the blade can be out of alignment and still cut straight.

The cross cut guide must be square to the crosscut guide slots.

When you have all three settings correctly aligned the table saw is a beautiful thing to operate.