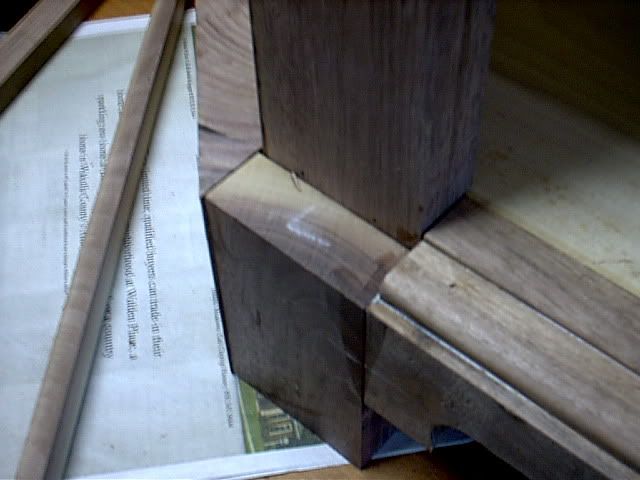

The walnut corner cupboard project is inching along--just the way I like it. This weekend I was able to install the foot buildup on each side along with a step up moulding on the front skirt. The drill--joint rough 5/4 wood with #7 and glue up. Use LN 40 1/2 to take off high spots. Use #7 to surface. Use wartime #4 1/2 with *Reedmaster Blade* for final finishing. Cut to size. Miter for fit. Use LN #62 to finish miter. Here is the picture of the completed foot build up.