Some folks asked for more details about how I etched the brass nameplate shown in this thread. It is just like making a silkscreen. Here are the details.

Necessary supplies:

- A piece of brass to etch

- Laser or inkjet transparencies.

- Photosensitive dry film

- Ferric chloride powder or pre-mixed etchant solution

- Washing soda (sodium carbonate)

- Lye or drano or something else VERY high pH.

- Fine steel wool or gray/white scotchbrite.

- Two plastic tupperwares

-A sheet of glass or pyrex dish.

- Hair dryer or other heat source.

Optional:

- Burn-in stick.

- Blacklight bulb.

1. Print two mirror image copies onto the transparency of the design you want to etch. The reason you want them mirrored is that you want the opaque surface as close to the photosensitive film as possible, so that light can't sneak in under the toner through the thickness of the transparency. The reason you want two is that one printout usually doesn't provide sufficient opacity. Align the two transparencies and secure them with tape. Hold your design up to the light to make sure it's fairly opaque. Fill in any thin spots with a sharpie.

2. Rub down the brass plate with scotchbrite to remove any oxides and expose shiny bare metal.

The following steps need to be done in no-daylight conditions, as UV will harden the photosensitive film. A room with windows closed and a LED lightbulb is good.

3. Cut the photosensitive film to approximate size and remove one side of the protective plastic. A piece of tape on a corner can help remove the protective plastic.

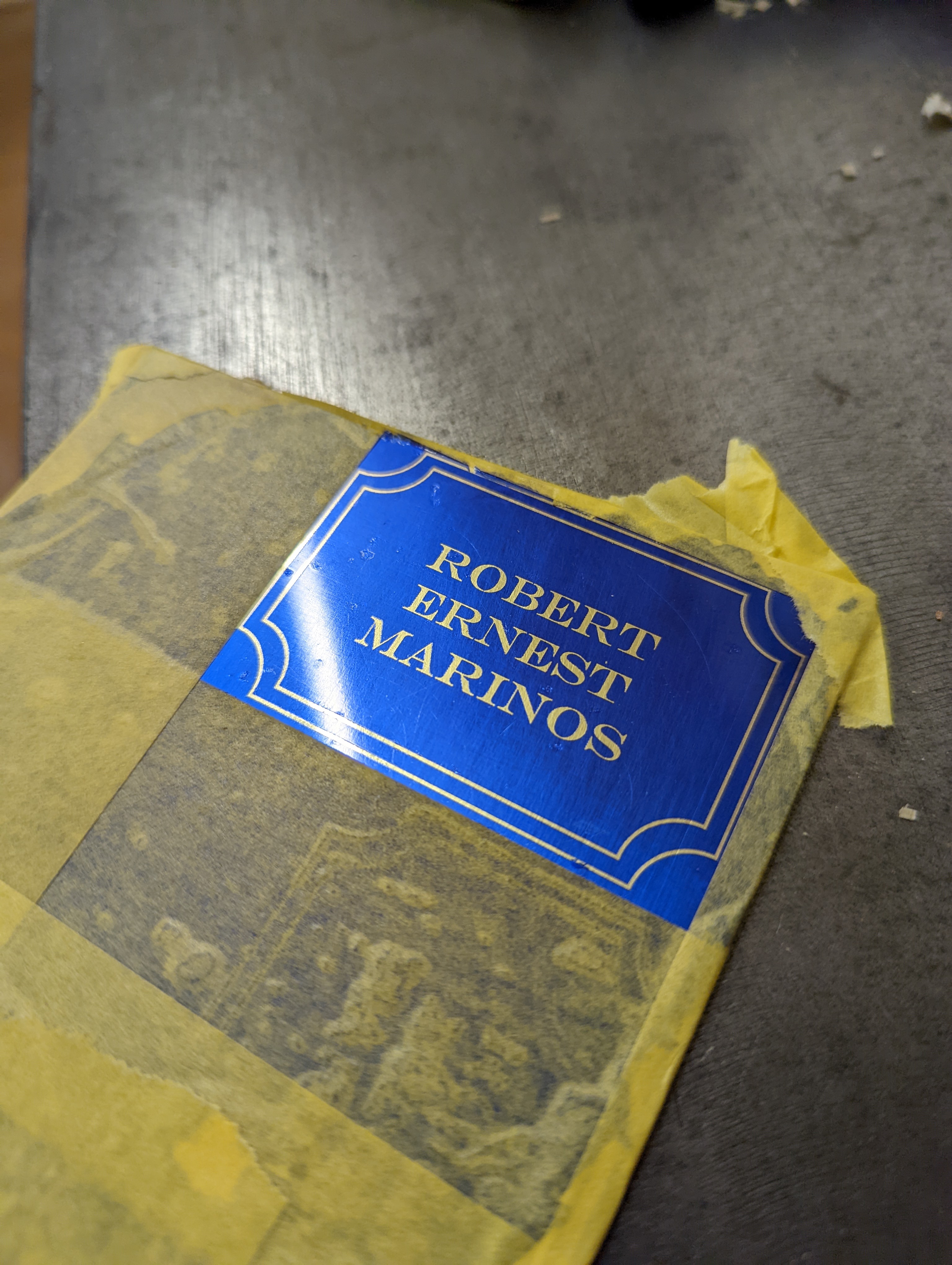

4. Working from one corner, press the photosensitive film onto the brass, working out any air bubbles as you go.

5. Heat the film with a hair dryer on high until the back of the brass plate gets hot, to adhere it to the plate.

6. Place the transparencies on top of the photosensitive film, and place the sheet of glass or pyrex dish on top of the transparencies to weight them down.

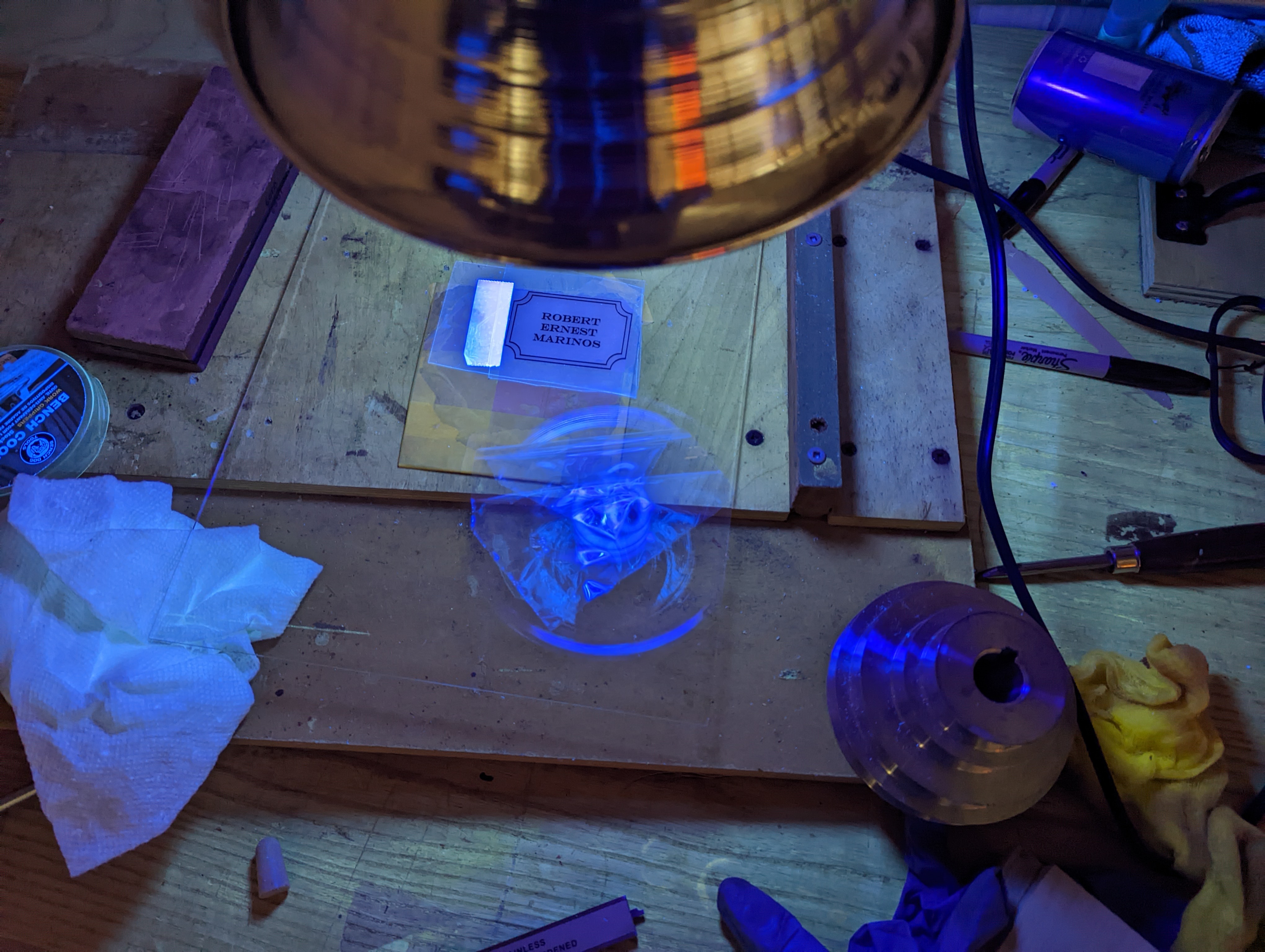

7. Expose the film using UV light. I bought a blacklight to do this for $10, but you can do it on a bright day outside too. Exposure time depends on UV light intensity, which in turn depends on distance from the bulb to the film, bulb wattage, and the bulb's specific light spectrum. You will need to experiment likely. I did 90 seconds with a 22W CFL blacklight bulb with a metal reflector, pictured below, about 6" in from the surface. If you go too long, you will lose fine detail from your etching or worst case you will harden the entire sheet. If you go too short, all the film will wash off instead of just the masked areas. I initially did 120 seconds but lost some detail so I dialed it back. I read somewhere that 5-8 minutes of bright sun exposure is good. When you remove the transparency you will clearly see which parts of the film have been hardened, as they are a darker blue.

8. Remove the protective plastic on the top of the photosensitive film.

9. Make a solution of washing soda, 0.5 oz in a quart of warm water. Put the plate in the solution and let it sit for 30 seconds. Then gently start rubbing the unexposed portions to remove the soft film. You should expose the bright metal underneath by doing so. Make sure you're attentive to details.

11. Mask off any additional parts of the plate you don't want etched using grease, tape or sharpie or anything else that will prevent the etchant from contacting the brass.

10. Make a ferric chloride solution BY ADDING FERRIC CHLORIDE TO WATER, not the other way around. (It will splatter and burn if you add water to FeCl3) Or just buy pre-made etchant. You want around 6 oz of ferric chloride in a pint of water. Use warm water.

12. Place the plate in the etchant and etch it for 1-3h, depending on how deep you want it. Keeping the etchant warm by putting it in a hot water bath will speed things up. Take it out and check the depth every 30m or so until you're satisfied with the depth.

13. Remove the plate and rinse.

14. Place the plate in a solution of 1 tbsp lye / pint of water to remove the hardened film. As with FeCl3, add lye to water, not the other way around.

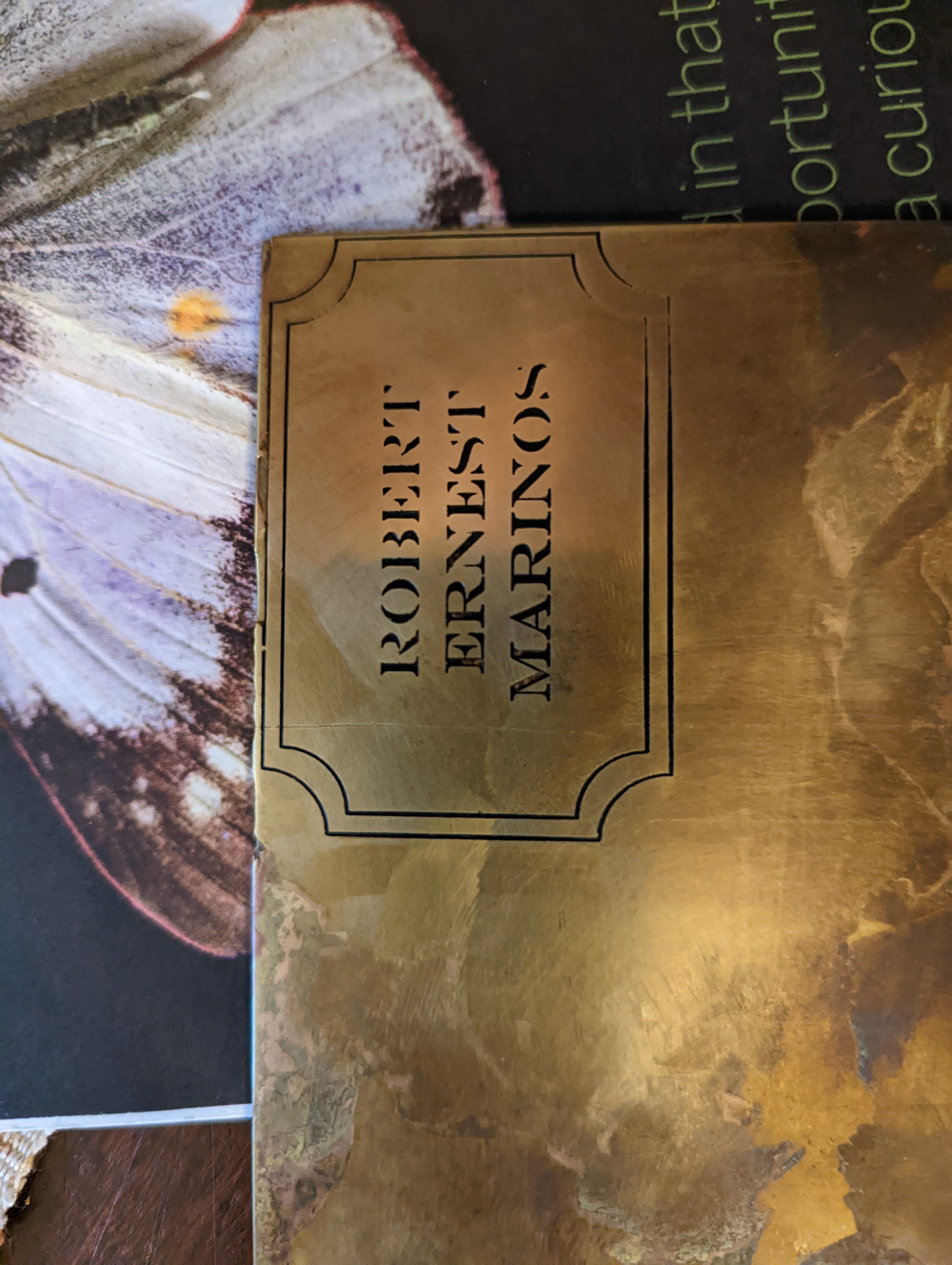

15. Your etch is done! Now you can cut and polish it. Pic below shows my overexposed etch with the loss of fine detail on the letters.

16. Optionally, fill the etched areas with burn-in stick to enhance contrast, but the etched areas will tarnish faster and should develop a natural patina quickly.

17. Etchant can be saved for later use. If it is to be disposed of, add a ton of washing soda to it to make it non-corrosive/non-toxic before dumping it.

Wow that was actually a lot of steps once I wrote it all out. But it's really not that hard!

Necessary supplies:

- A piece of brass to etch

- Laser or inkjet transparencies.

- Photosensitive dry film

- Ferric chloride powder or pre-mixed etchant solution

- Washing soda (sodium carbonate)

- Lye or drano or something else VERY high pH.

- Fine steel wool or gray/white scotchbrite.

- Two plastic tupperwares

-A sheet of glass or pyrex dish.

- Hair dryer or other heat source.

Optional:

- Burn-in stick.

- Blacklight bulb.

1. Print two mirror image copies onto the transparency of the design you want to etch. The reason you want them mirrored is that you want the opaque surface as close to the photosensitive film as possible, so that light can't sneak in under the toner through the thickness of the transparency. The reason you want two is that one printout usually doesn't provide sufficient opacity. Align the two transparencies and secure them with tape. Hold your design up to the light to make sure it's fairly opaque. Fill in any thin spots with a sharpie.

2. Rub down the brass plate with scotchbrite to remove any oxides and expose shiny bare metal.

The following steps need to be done in no-daylight conditions, as UV will harden the photosensitive film. A room with windows closed and a LED lightbulb is good.

3. Cut the photosensitive film to approximate size and remove one side of the protective plastic. A piece of tape on a corner can help remove the protective plastic.

4. Working from one corner, press the photosensitive film onto the brass, working out any air bubbles as you go.

5. Heat the film with a hair dryer on high until the back of the brass plate gets hot, to adhere it to the plate.

6. Place the transparencies on top of the photosensitive film, and place the sheet of glass or pyrex dish on top of the transparencies to weight them down.

7. Expose the film using UV light. I bought a blacklight to do this for $10, but you can do it on a bright day outside too. Exposure time depends on UV light intensity, which in turn depends on distance from the bulb to the film, bulb wattage, and the bulb's specific light spectrum. You will need to experiment likely. I did 90 seconds with a 22W CFL blacklight bulb with a metal reflector, pictured below, about 6" in from the surface. If you go too long, you will lose fine detail from your etching or worst case you will harden the entire sheet. If you go too short, all the film will wash off instead of just the masked areas. I initially did 120 seconds but lost some detail so I dialed it back. I read somewhere that 5-8 minutes of bright sun exposure is good. When you remove the transparency you will clearly see which parts of the film have been hardened, as they are a darker blue.

8. Remove the protective plastic on the top of the photosensitive film.

9. Make a solution of washing soda, 0.5 oz in a quart of warm water. Put the plate in the solution and let it sit for 30 seconds. Then gently start rubbing the unexposed portions to remove the soft film. You should expose the bright metal underneath by doing so. Make sure you're attentive to details.

11. Mask off any additional parts of the plate you don't want etched using grease, tape or sharpie or anything else that will prevent the etchant from contacting the brass.

10. Make a ferric chloride solution BY ADDING FERRIC CHLORIDE TO WATER, not the other way around. (It will splatter and burn if you add water to FeCl3) Or just buy pre-made etchant. You want around 6 oz of ferric chloride in a pint of water. Use warm water.

12. Place the plate in the etchant and etch it for 1-3h, depending on how deep you want it. Keeping the etchant warm by putting it in a hot water bath will speed things up. Take it out and check the depth every 30m or so until you're satisfied with the depth.

13. Remove the plate and rinse.

14. Place the plate in a solution of 1 tbsp lye / pint of water to remove the hardened film. As with FeCl3, add lye to water, not the other way around.

15. Your etch is done! Now you can cut and polish it. Pic below shows my overexposed etch with the loss of fine detail on the letters.

16. Optionally, fill the etched areas with burn-in stick to enhance contrast, but the etched areas will tarnish faster and should develop a natural patina quickly.

17. Etchant can be saved for later use. If it is to be disposed of, add a ton of washing soda to it to make it non-corrosive/non-toxic before dumping it.

Wow that was actually a lot of steps once I wrote it all out. But it's really not that hard!