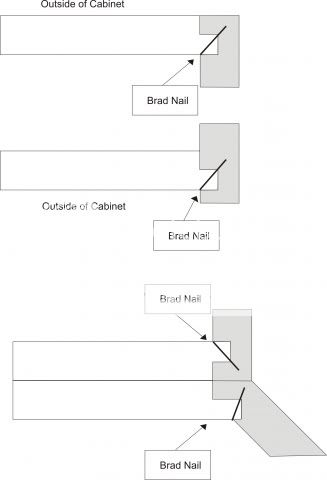

I am making kitchen cabinets and am worried about how i decided to attach the face frames. I assembled the face frames using pocket screws. The face frames had rabbits in them to align with the cabinet boxes.

and

I then attached the face frames to the boxes with glue and brads. Now that i am finished i am wondering if this is going to be strong enough? If it isn't i am going to look like this:BangHead: but i had seen cabinets that looked like they were made this way and am hoping i guessed right about the glue and brads to hold it all together.

and

I then attached the face frames to the boxes with glue and brads. Now that i am finished i am wondering if this is going to be strong enough? If it isn't i am going to look like this:BangHead: but i had seen cabinets that looked like they were made this way and am hoping i guessed right about the glue and brads to hold it all together.