You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone ever stabilized their own wood?

- Thread starter Truefire

- Start date

- Status

- Not open for further replies.

I've been looking at a chamber that a guy in Texas makes, here's the link

http://www.turntex.com/index.php?option=com_virtuemart&Itemid=121

He's got some videos on there that are really great for explaining how it works, and sells the stabilizing material he uses. His chamber looks pretty easy to make.

http://www.turntex.com/index.php?option=com_virtuemart&Itemid=121

He's got some videos on there that are really great for explaining how it works, and sells the stabilizing material he uses. His chamber looks pretty easy to make.

- Cool Scott, keep us posted if you would not mind sharing your ideas and design. Have you ever used Minwax wood hardener before in other capacities Smith or no? Prior to using same in a vacuum chamber? Would it work to impregnate the cellular makeup of small pieces submerged at 1 atm? I have never used this stuff before and not aware of its viscosity and whether or not it is readily absorbed by most woods. Understanding a vacuum chamber is the only way in which to reach for solution to reach deep inner cells but would the Minwax work on smaller pieces well enough to somewhat stabilize the outer portions? What do you all think?

- Thanks Phillip, appreciate the link, I am familiar with this guy and his work. Not really what I was seeking, just wondering if others had some input regarding home bound stabilizing and plans. I certainly would never replicate a guy's chamber that is providing him with 'bread and butter'. I have not devoted the necessary research time at the present to understand some of the science behind stabilizing and vacuum chambers. I have never really used vacuum chambers in the past so was seeking input regarding that aspect as well.

Thanks guys, Chris

- Thanks Phillip, appreciate the link, I am familiar with this guy and his work. Not really what I was seeking, just wondering if others had some input regarding home bound stabilizing and plans. I certainly would never replicate a guy's chamber that is providing him with 'bread and butter'. I have not devoted the necessary research time at the present to understand some of the science behind stabilizing and vacuum chambers. I have never really used vacuum chambers in the past so was seeking input regarding that aspect as well.

Thanks guys, Chris

I have one of turntex chambers

There is also a guy on woodbarter that sells a class chamber that looks like it is made out of glass tube.

seen one also made out of a stainless steel pot with acrylic lid on ebay.

The resins I have only tried turntex but the buy on woodbarter sells some also.

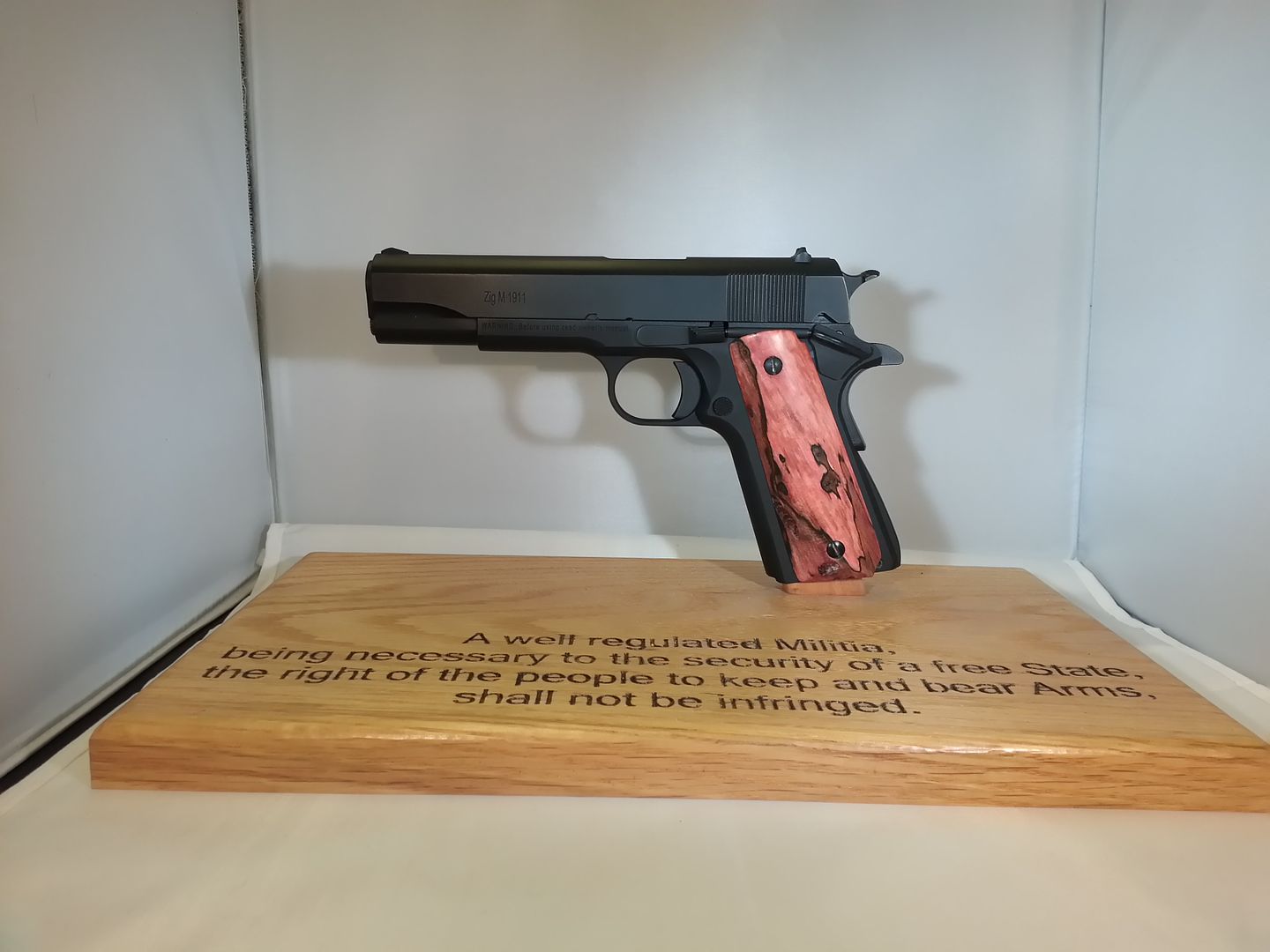

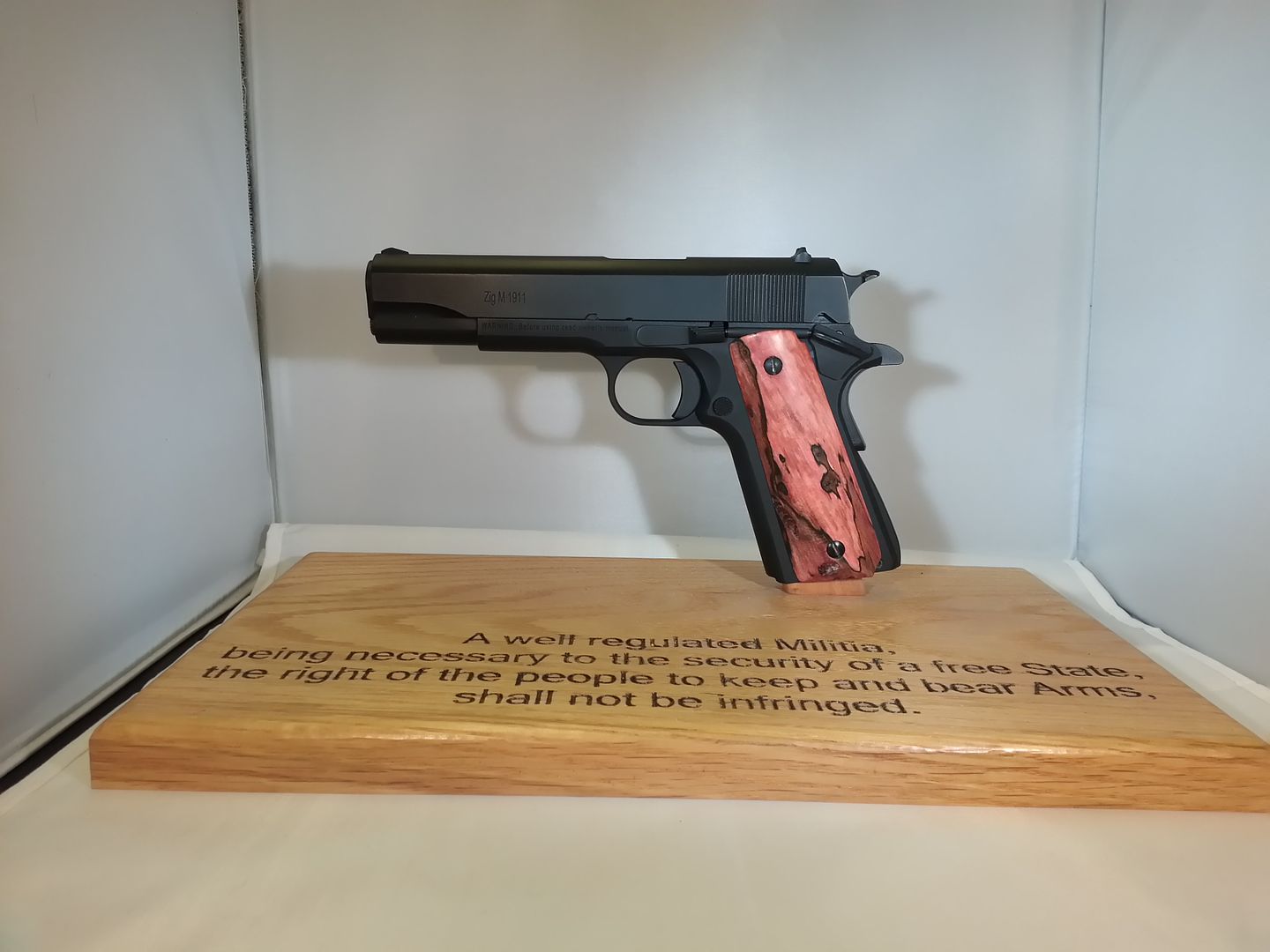

before

after dyed red,

cured ended up not being red became pink after curing

finished

There is also a guy on woodbarter that sells a class chamber that looks like it is made out of glass tube.

seen one also made out of a stainless steel pot with acrylic lid on ebay.

The resins I have only tried turntex but the buy on woodbarter sells some also.

before

after dyed red,

cured ended up not being red became pink after curing

finished

John I like that man....nice. Are you pleased with the chamber? Is that color completely saturating the inner most portions of your wood blanks held in your gloved hands? If so, that is pretty awesome. I cannot wait to begin stabilizing some wood, one more little thing to give me an edge at some of the festivals. Your pistol job is super cool and unique...its honestly probably the only one of its kind in America. Did the wood work easily after being stabilized or did you just dye the wood only?

Chris

Chris

- Cool Scott, keep us posted if you would not mind sharing your ideas and design. Have you ever used Minwax wood hardener before in other capacities Smith or no? Prior to using same in a vacuum chamber? Would it work to impregnate the cellular makeup of small pieces submerged at 1 atm? I have never used this stuff before and not aware of its viscosity and whether or not it is readily absorbed by most woods. Understanding a vacuum chamber is the only way in which to reach for solution to reach deep inner cells but would the Minwax work on smaller pieces well enough to somewhat stabilize the outer portions? What do you all think?

Thanks guys, Chris

Chris, I've never used it before. According to the pen turners it does a good job.

Chamber is very good quality but it did take me almost 6 month to get it after ordering it, but i only had to put a deposit to get it made.It was fully refundable if I wanted to cancel it.John I like that man....nice. Are you pleased with the chamber? Is that color completely saturating the inner most portions of your wood blanks held in your gloved hands? If so, that is pretty awesome. I cannot wait to begin stabilizing some wood, one more little thing to give me an edge at some of the festivals. Your pistol job is super cool and unique...its honestly probably the only one of its kind in America. Did the wood work easily after being stabilized or did you just dye the wood only?

Chris

It does get fully saturated if you follow the process on stabilizing it.

here is a link to the glass chamber and videos.

http://woodbarter.com/showthread.php?tid=6856&highlight=stabilizing

Dying on the other hand when the color of the solution looks good double the color.

The red blanks in the picture are the same blanks on the handgun.)I did make the grips in the picture)

Wood works the same and finish i just sanded it and the buffed it out.

I think i have a couple of Spalted maple pot call blanks done stabilized clear,but will be awhile before I can get to them. they measure approximate 2 are 5x5x1 and 1 is 5x5 and slightly less than 1 in.

If you would like to try let me know we may be able to work a trade out.

I used a large mason jar and a home vacuum sealer. Left in in about a week and they turned out ok. I started with the equivalent size of a duck call blank but ended up cutting it up after the process into pen blanks. Need to turn a call for my nephew so I am going to try this process again

- Cool Scott, keep us posted if you would not mind sharing your ideas and design.

Thanks guys, Chris

Chris, attached are a couple of photos of my chamber. I simply used an old Newmans Own Pasta Sauce jar and drilled the lid for a bulkhead fitting. I attached a standard air hose coupler to the bulkhead fitting, and attach it to my vacuum pump via a standard shop air hose.

When I first put the blanks into the hardener, I could see very fine bubbles working their way out of the wood, so absorbs a small amount via soaking (see first photo). Once I turn on the vacuum pump, things really get interesting with a ton of bubbles coming out! My first lesson learned is that I need a taller jar, as when I first started I had to manually cycle the vacuum pump on and off to keep it from sucking foam into the hose.

Right now I'm only pulling 20 inches of vacuum.

Here is the vacuum chamber with no vacuum on it.

This is what it looks like as soon as the vacuum pump kicks in!

Thanks for sharing guys. Scott, that is a neat setup...a larger pickle jar and perhaps you would be "Kosher"...:rotflm: But seriously though, thanks a million for sharing. It is always neat to see other's approaches and ideas. I had thought of making mine out of 4" -6" PVC pipe but really wanted to be able see the action and monitor, then I wondered how I would provide sufficient sealing within the threads of caps. Thus, I have not pursued any further right now. Had other things going and didn't need yet another project so I just decided to go with the TurnTex chamber. I have placed an order with Curtis, I like the square vat and being able to monitor through clear walls. A + is the wooden top with gasket, really cool.

20 inches of vacuum, that is almost the atm on top of Mt. Sinai as I recall from movie years ago. Could you imagine a naturally stabilized piece of wood crafted into a Mt Sinai pen, now that baby would sell. Could ask some of those diehard mountain climbers to do this for us. Seriously though, in theory, it could be done I suppose. You have to to admit, it would be cool. I guess you would have to have the wood and stabilizer sealed at in a jar while here at 1 atm, then crack it open upon the arrival. But it would return to equalibrium after returning i suppose...oh heck, worth the thought.

Chris

20 inches of vacuum, that is almost the atm on top of Mt. Sinai as I recall from movie years ago. Could you imagine a naturally stabilized piece of wood crafted into a Mt Sinai pen, now that baby would sell. Could ask some of those diehard mountain climbers to do this for us. Seriously though, in theory, it could be done I suppose. You have to to admit, it would be cool. I guess you would have to have the wood and stabilizer sealed at in a jar while here at 1 atm, then crack it open upon the arrival. But it would return to equalibrium after returning i suppose...oh heck, worth the thought.

Chris

You will need to get down to 28-29 inches of vacuum to get complete penetration of the stabilizing liquid.

Did you order the cactus juice from Curtis also?

yes i purchased some with order

Foaming under vacuum is expected at the outset. A manually adjusted bleeder valve between the jar and pump allows slow and incremental increases towards full vacuum as the air is extracted.

I think that the TurnTex setup includes this valve.

Jeff, thanks for the advice. My pump has a bleeder valve on it; now I know why!

Jeff what do you do? "Open the bleeder valve fully initially and then close it shut a little bit at the time while monitoring the air bubbles dissipation? " I do not have one of the chambers and thus have never experimented with the process. I guess when a unit is in hand, it is straightforward and intuitive. I understand the vacuum atm achieved has everything to do with the density of the wood being stabilized.

Was wondering what is the maximum vacuum anyone has ever had to achieve in order to obtain a good stabilization?

Reason I ask, is I plan on using the process to stabilize spunky and softer woods primarily. However, I would like to fill cracks in harder, denser woods occasionally with a dyed solution thereby salvaging some of my high-end woods and creating some neat pieces in the process.

thanks, Chris

Was wondering what is the maximum vacuum anyone has ever had to achieve in order to obtain a good stabilization?

Reason I ask, is I plan on using the process to stabilize spunky and softer woods primarily. However, I would like to fill cracks in harder, denser woods occasionally with a dyed solution thereby salvaging some of my high-end woods and creating some neat pieces in the process.

thanks, Chris

Chris,

Short story shorter. I'm a chemist and have used vacuum pumps for many years. No wood stabilization experience.

Yes, when you begin pulling a vacuum all of the air going into the pump is coming through the bleeder valve. Close it a little until you begin seeing air bubbles in the tank so you're beginning to pull a vacuum there. If it froths too much ease open the bleeder and sneak up on it a little at a time. There should be no frothing at the top of the tank or liquid getting into the line (that's bad for your pump). As the air is sucked out of the wood pores the bubbling and frothing will subside to the point that you'll have a full vacuum applied to the chamber with the valve fully closed so let it go on for about 1.5 hours with slight agitation here and there to clear the bubbles trapped on the bottom.

The Turn Tex videos are instructive too.

Short story shorter. I'm a chemist and have used vacuum pumps for many years. No wood stabilization experience.

Yes, when you begin pulling a vacuum all of the air going into the pump is coming through the bleeder valve. Close it a little until you begin seeing air bubbles in the tank so you're beginning to pull a vacuum there. If it froths too much ease open the bleeder and sneak up on it a little at a time. There should be no frothing at the top of the tank or liquid getting into the line (that's bad for your pump). As the air is sucked out of the wood pores the bubbling and frothing will subside to the point that you'll have a full vacuum applied to the chamber with the valve fully closed so let it go on for about 1.5 hours with slight agitation here and there to clear the bubbles trapped on the bottom.

The Turn Tex videos are instructive too.

Jeff thanks, just as I assumed. I thought it would be fairly intuitive and straightforward however I asked anyway because I learned long ago not to assume. Most everything in life is a science and as I recall from chemistry, one of the most counter-intuitive disciplines in my mind, never assume and use common sense, especially when it comes to problem solving in that discipline.

Where were you a few years ago when I was wading through some of that coursework? :BangHead: I made it out brother, some scars, sniffles and tattered shoes but here we are.

I'm looking forward to being able to stabilize some of the softer woods that I get my hands on from time to time, this chamber should give me a little more to offer individuals at festivals and the like. I have to throw away some really beautiful, softer woods from time to time simply because it is not conducive to my purposes. But now I will be able to keep this stuff, that's neat.

Thanks again Jeff,

chris

Where were you a few years ago when I was wading through some of that coursework? :BangHead: I made it out brother, some scars, sniffles and tattered shoes but here we are.

I'm looking forward to being able to stabilize some of the softer woods that I get my hands on from time to time, this chamber should give me a little more to offer individuals at festivals and the like. I have to throw away some really beautiful, softer woods from time to time simply because it is not conducive to my purposes. But now I will be able to keep this stuff, that's neat.

Thanks again Jeff,

chris

As an update to my earlier post, I've learned a few things about the hardening process this week, and wanted to share some "DON'T's"....

DON'T use Minwax wood hardener in a vacuum setup! It is primarily acetone, which evaporates under vacuum! I keep having to refill my vacuum chamber because the level keeps dropping.

DON'T use a vacuum container that is only barely taller than your blanks. The problem is that the foam builds up and can get sucked into your vacuum hose.

DON'T use cheap plastic jars with Minwax wood hardener (the one with the acetone in it...), or expect to find a little "surprise" after a day or so of soaking....

DON'T use Minwax wood hardener in a vacuum setup! It is primarily acetone, which evaporates under vacuum! I keep having to refill my vacuum chamber because the level keeps dropping.

DON'T use a vacuum container that is only barely taller than your blanks. The problem is that the foam builds up and can get sucked into your vacuum hose.

DON'T use cheap plastic jars with Minwax wood hardener (the one with the acetone in it...), or expect to find a little "surprise" after a day or so of soaking....

- Status

- Not open for further replies.

LATEST FOR SALE LISTINGS

-

-

Graco 395 FinishPro air assisted airless sprayer for sale

- Started by RobH

- Replies: 1

-

-

-