You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lathe

-

Glueing the tubes.

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

5 coats of spray laquer

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

2 coats of sealcoat

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

Ready for sanding

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

Round!

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

Getting it round

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

Drilling the blanks

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

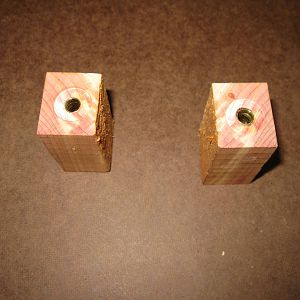

Blanks mounted

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

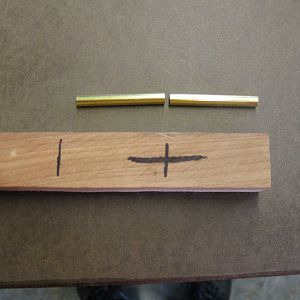

Blanks with tubes

- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

-

First Pen

Preparing to cut the blanks- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

-

-

-

First Pen

Mandrel saver in lathe- Acelectric

- Media item

- lathe pen turning

- Comments: 0

- Album: First Pen

-

-

Side view of lathe

I have finished the main base and here it is in it new home waiting for a few extra add ons.- oldetoolworkshop

- Media item

- german lathe pole spring

- Comments: 0

- Category: Tools & Equipment Photos

-

Nova chuck runout

I bought a used Nova Midi and first run up there was visible runout so I checked it with a dial indicator. Runout on the outside of the jaws was ~0.040; but is tough to check. Then I chucked a piece of PVC (it was the best thing I could find) and runout was ~0.015. Considering the PVC may not...- Rick M

- Thread

- lathe nova runout

- Replies: 23

- Forum: Woodturning

-

Spring Pole Lathe - Under construction

Here is my SPL as it is now. Needs more work.- oldetoolworkshop

- Media item

- lathe pole spring

- Comments: 0

- Category: Member Galleries

-

Very low cost way of measuring tool speed.

After switching my lathe to a variable speed DC motor I didn't know it’s speed range so rather than buying a digital tachometer for a one off measurement I used some old tech… a homemade strobe tachometer. Turntables had a series of lines around the platter so that with a strobe you could set...- Rick M

- Thread

- fluorescent lathe rpm speed strobe tachometer

- Replies: 5

- Forum: "How To" Forum

LATEST FOR SALE LISTINGS

-

SOLD -- $75: Gast moa v113 Vacuum Pump Veneer, 60" bag and board

- Started by peterdnight

- Replies: 1

-

GONE: Gladiator 5 cleats, 10 hangers, Paper Towel and Shelf

- Started by peterdnight

- Replies: 3

-

SOLD -- $100 Makita mac700 portable air + grex pin nailer + 2 others + 50' hose

- Started by peterdnight

- Replies: 1

-

-