There's nothing 'original' here, I just thought I'd post in case others had not considered such a jig. I suspect others (Joe Scharle, the jigmeister) have posted something like this back in the archives, but pics haven't necessarily migrated to the new platform.

Anyways, I am working on a sheet good project, something I haven't done very often. I need to dado shelves into the sides of a 3 unit set of built-in bookcase/cabinets. So I needed a consistent method to dado.

Many 'exact width' use the concepts of

1. an undersize bit and two passes to establish the two sides - I do this too

2. using the actual material to set the width of the jig - I also do this.

The few videos I watched (Wood Whisperer and other similar ones) were helpful in establishing the types of pieces needed and general dimensions. However they all seemed to use either a bushing or the router plate edge to establish the position, and quite frankly did not appeal to me. Doing so requires use of the same router/bit combo, or bushing/bit combo, each time.

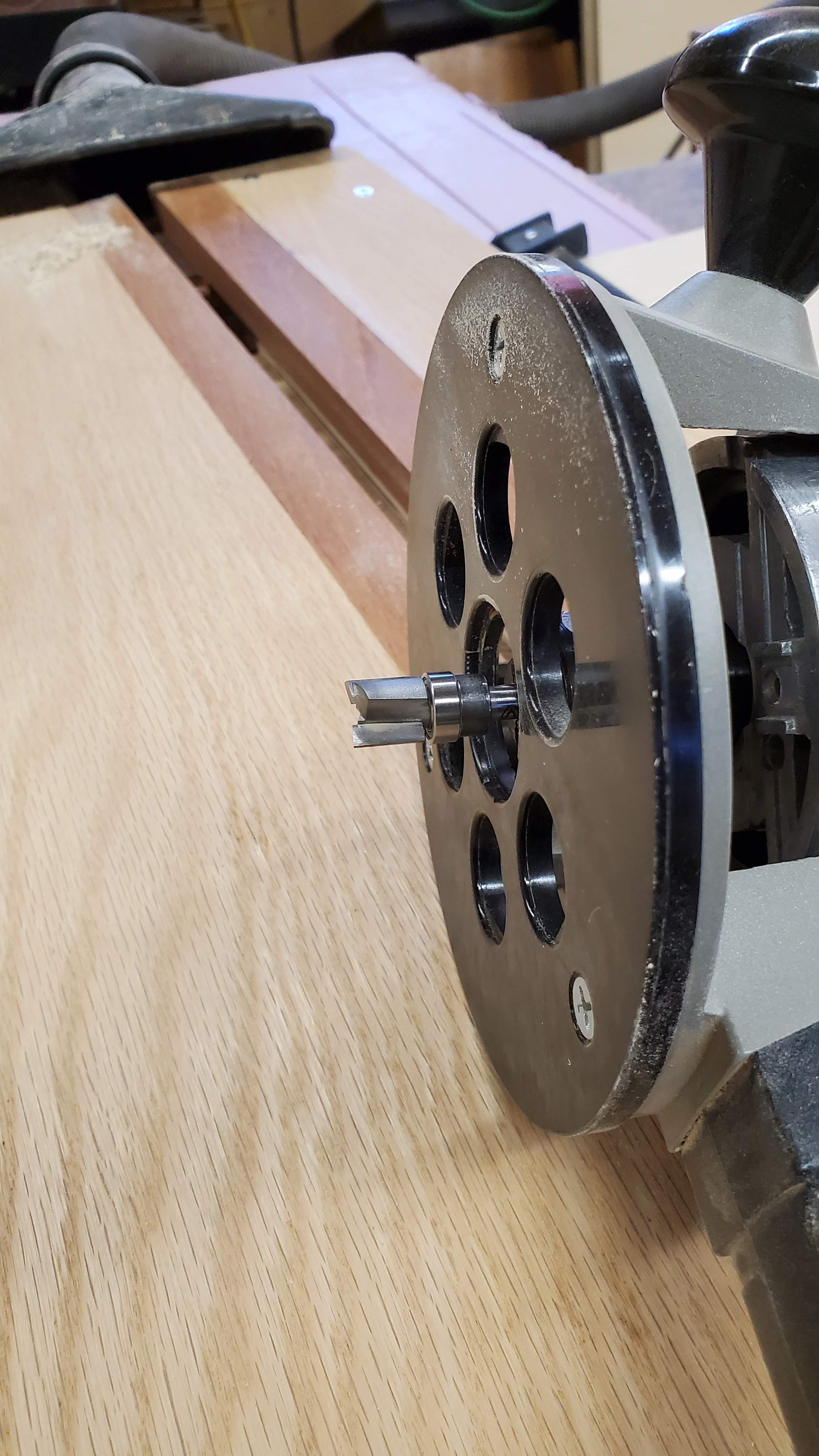

So I purchased a top bearing 1/2" wide bit from Klingspor's (1/4" shank was the only way it came) and used that. So far it has worked flawlessly.

Hints from videos that I found useful were:

1. Clamping the piece into the jig to establish a tight fit dado.

2. Clamping the jig onto the piece helps maintain position

3. Ensuring the reference surface is straight and flat will help.

Here's a few pics of the jig in action; 2nd one shows the top bearing bit.

Sorry, not the greatest pics for a fully explanation, but if you want that there are more than a few videos to see. I wanted a jig that could lay flat on a bench and so put the slots below and the knobs above. THis will handle a 24" width, so I am cutting the shelf sides, then ripping to width. Should ensure perfect alignment.

Anyways, I am working on a sheet good project, something I haven't done very often. I need to dado shelves into the sides of a 3 unit set of built-in bookcase/cabinets. So I needed a consistent method to dado.

Many 'exact width' use the concepts of

1. an undersize bit and two passes to establish the two sides - I do this too

2. using the actual material to set the width of the jig - I also do this.

The few videos I watched (Wood Whisperer and other similar ones) were helpful in establishing the types of pieces needed and general dimensions. However they all seemed to use either a bushing or the router plate edge to establish the position, and quite frankly did not appeal to me. Doing so requires use of the same router/bit combo, or bushing/bit combo, each time.

So I purchased a top bearing 1/2" wide bit from Klingspor's (1/4" shank was the only way it came) and used that. So far it has worked flawlessly.

Hints from videos that I found useful were:

1. Clamping the piece into the jig to establish a tight fit dado.

2. Clamping the jig onto the piece helps maintain position

3. Ensuring the reference surface is straight and flat will help.

Here's a few pics of the jig in action; 2nd one shows the top bearing bit.

Sorry, not the greatest pics for a fully explanation, but if you want that there are more than a few videos to see. I wanted a jig that could lay flat on a bench and so put the slots below and the knobs above. THis will handle a 24" width, so I am cutting the shelf sides, then ripping to width. Should ensure perfect alignment.